The Future of Label Printing: Combining Multiple Techniques for Excellence

Combination printing refers to the process where more than two printing methods are used on a single machine to complete the processing of a print product in one go. Labels produced through combination printing fully display the characteristics of different printing methods and skillfully combine their respective advantages to ultimately achieve the designer’s original creativity.

Labels produced by combination printing are not only beautifully printed but also possess certain anti-counterfeiting features. Due to the complexity of the combination printing process and the high requirements for hardware equipment, it is difficult for most printing companies to process due to software and hardware limitations.

It can be said that labels produced by combination printing are the fine products in the label family, representing the highest level of printing technology and the product of the combination of materials, ink, equipment, and operational techniques. Below, I will discuss the application and prospects of combination printing in the label printing industry.

Market Demand

As market demands for label beauty and anti-counterfeiting performance continue to increase, traditional single printing methods are increasingly unable to meet the needs of users. For anti-counterfeiting and aesthetic reasons, modern labels have higher process requirements, and many companies hope to equip their products with special labels: either requiring special process treatment to achieve special effects or requiring the product to reflect the characteristics of various printing methods.

For example, some labels have a metallic base color with screen printing and flexographic effects on the surface, requiring the combination of flexography, screen printing, and intaglio; others have effects of both intaglio and flexographic printing on the surface; similarly, another type of label has both gold-stamping metallic luster and screen printing effects, and so on.

Moreover, some labels require the ink layer of the solid area to reach a certain thickness while the dot area needs to be very delicate, along with gold-stamping requirements. Such design schemes cannot be achieved by traditional single printing methods. Therefore, it is necessary to combine several printing methods to meet their design needs.

Common Processes and Advantages

In theory, various printing methods can be combined arbitrarily to achieve process objectives. However, considering factors such as production efficiency, cost, and scrap rate, combinations of more than two printing methods are not widely used in production.

Common combination printing methods include: flexography and screen printing; flexography and intaglio; flexography and offset; flexography and letterpress; letterpress and screen printing; flexography, screen printing, and intaglio; flexography, screen printing, and letterpress; flexography, offset, and screen printing; offset, screen printing, flexography, and intaglio; flexography combined with post-processing processes such as cold foil stamping, hot foil stamping, laminating, die cutting, embossing, slitting, and die cutting; flexography, screen printing combined with post-processing processes; flexography, screen printing, intaglio combined with post-processing processes; screen printing, intaglio, letterpress combined with post-processing processes; offset, flexography, screen printing, intaglio combined with post-processing processes, etc.

To understand the advantages of combination printing, it is necessary to understand the advantages and disadvantages of various printing methods. Below, I will briefly introduce the advantages and disadvantages of various printing methods:

Advantages of Offset Printing

– Low printing cost, accurate overprinting, can be controlled within ±0.02mm;

– Dot reproduction, the transition from transition dots to solid dots is very beautiful, and will not exceed 10% to 15% in the most easily deformed dot area;

– High printing quality, the usual printing resolution can reach 150-300lpi.

Disadvantages: The print is not thick enough when printing solids, sometimes large solids need to be printed twice, and it is difficult to maintain consistent ink color. This disadvantage is particularly prominent when printing solids on the surface of film materials.

Advantages of Flexographic Printing

1. **Environmental Protection**: Flexographic printing uses UV ink and water-based ink, which are quite environmentally friendly, non-toxic, odorless, and meet FDA hygiene requirements. It is a very common printing method in Europe and America.

2. **Fast Printing Speed**: The normal printing speed of a flexible plate can usually reach more than 100m/min.

3. Due to the short ink path system used in flexographic printing, the ink supply is stable, and flexographic printing performs excellently in terms of ink saturation and consistency, with bright and beautiful colors. The printed product can maintain consistent ink color and achieve excellent solid, line printing, and varnishing.

4. Flexographic printing is suitable for a wide range of substrates.

Advantages of Screen Printing

Screen printing has high ink coverage and color strength, with an ink layer thickness of 20-100μm. Screen printing is suitable for special surface treatments, embossed surface decorations, priming of transparent films, and printing of Braille, etc. Disadvantages: Slow printing speed, and rotary screen printing is relatively expensive.

Advantages of Intaglio Printing

Excellent solid printing effect (ink layer thickness up to 30μm) and metallic ink printing effect. The usual printing resolution of intaglio printing is 100-359lpi; high printing quality, fast speed, good color consistency, good material adaptability, and high plate durability.

Disadvantages: Usually uses solvent-based inks, which are not environmentally friendly. Although water-based inks for intaglio printing are also under development, they cannot yet replace solvent-based inks. In addition, intaglio printing has insufficient ability to print fine dots, and small dots are easy to lose.

Value of Combination Printing

Combination printing combines the advantages of various printing methods to produce high-quality printed products, which can present a luxurious product appearance when used for luxury goods printing.

Combination printing can add value to printed products, make products more valuable and competitive, thereby obtaining greater profits; combination printing also provides an innovative platform, allowing processes to be combined arbitrarily and designs to be freer.

Since all printing and post-processing of the product are completed on one machine without intermediate links, product quality is easy to control, thereby shortening the product delivery period.

Using combination printing, production and processing are more convenient, costs are saved, and production efficiency is further improved.

Due to the application of many advanced technologies in combination printing, the investment in equipment is higher, which also increases the entry threshold and the difficulty of imitation, thereby making the printed products produced by printing companies have irreproducibility.

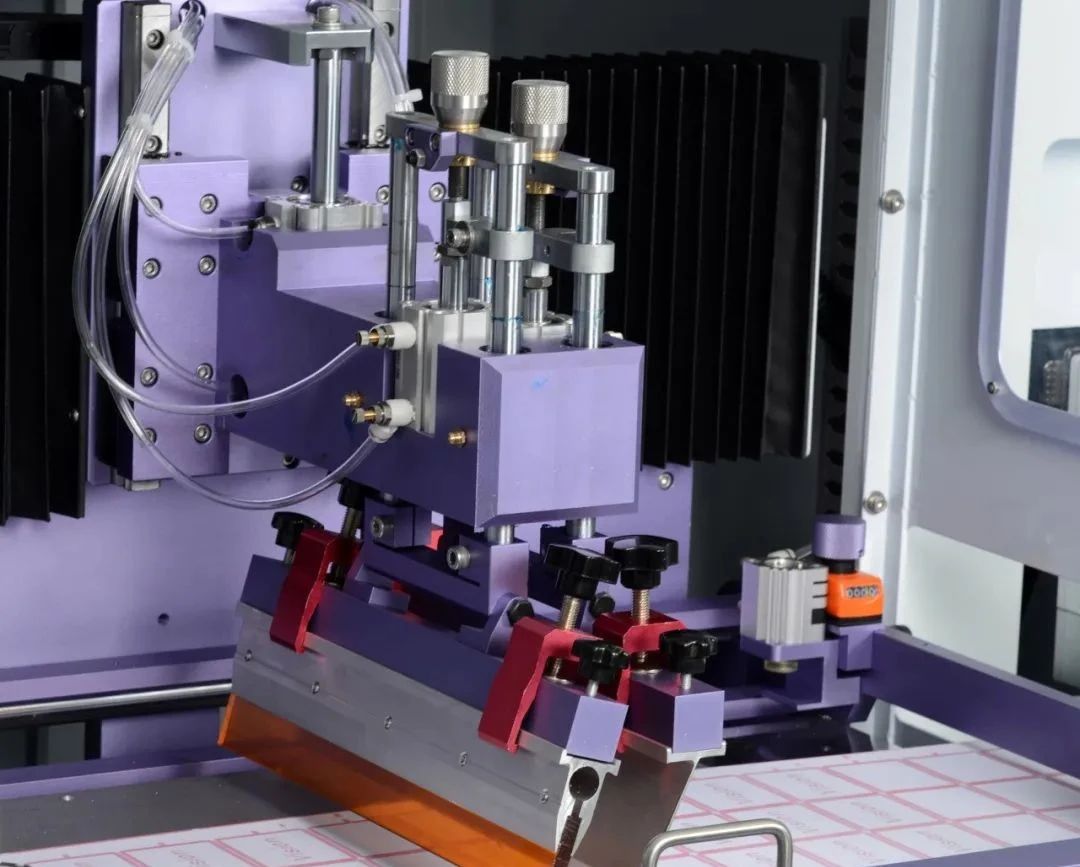

The MDF multifunctional post-press combination machine developed and produced by Weitian Intelligent can combine multiple printing methods and can definitely meet your printing needs.