Reverse UV, frosted UV, and frosted embossing are all processes that can create a frosted granular texture on the surface of packaging, adding a comfortable frosted feel. The frosted effect gives a sense of thickness and stability, and it also stands out in terms of texture. However, these three processes are different, each with its own advantages. How do we usually distinguish between them?

**Process Principles**

1. Reverse UV

Utilizes the “mutual exclusion” principle between coating-type UV varnish and base UV varnish (ink fountain-type UV varnish) to achieve a one-time effect of concave-convex texture and different gloss levels. That is, applying varnish in areas without base oil achieves a bright effect, while applying varnish in areas with base oil achieves a matte effect.

This process can control the brightness (or the strength of shrinkage and wrinkling) after UV varnishing by adjusting the amount of UV base oil or the size of the dots.

2. **UV Printing Frosted**

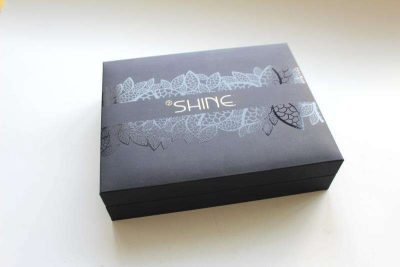

UV frosted printing, also known as UV metal etching simulation printing, involves printing a layer of uneven semi-transparent ink on a substrate with a metallic mirror finish (such as gold or silver cardboard). After UV curing, it produces an effect similar to a shiny metal surface that has been etched or frosted. In the film industry, applying a frosted process to polyester film or other film materials gives the printed product a soft, solemn, and elegant aesthetic. Additionally, adding an anti-scratch agent to the UV ink increases the product’s durability against scratches.

3. **Frosted Embossing**

Embossing is a common printing process. It uses concave-convex molds to create plastic deformation on the surface of the printed material under certain pressure, thereby artistically processing the surface of the printed product.

**Advantages and Identification**

**01 Advantages of Reverse UV**

– Enhances the lightfastness of ink and increases resistance to heat and moisture, protecting the print and beautifying the product.

– Allows for two different gloss levels on the same print, expanding applications in various product packaging such as promotional items, gifts, calendars, crafts, cigarette boxes, liquor boxes, food boxes, etc.

– Achieves a stronger contrast in brightness, enhancing the effect of the varnish.

– Ensures accurate overprinting and high printing precision due to the use of offset printing for non-bright areas.

**02 Material Requirements for Reverse UV**

– Requires smooth paper with low ink absorption to maintain gloss and varnish effect.

– Avoids excessive powder spraying, which can affect the varnish effect.

– Ensures ink is fully dried before surface treatment.

– Selects patterns for processing, filling in the base color for frosted areas and leaving bright areas empty.

– Uses paper with low absorbency and good surface quality.

– Adds minimal UV curing agents to avoid compromising the reverse UV effect.

– Selects materials with appropriate moisture content to prevent warping or cracking.

**03 Advantages of Frosted UV**

– Provides a finer frosted effect than traditional methods due to the precision of the printing press.

– Faster production speed as the frosted effect is applied simultaneously with the color printing.

– Lower cost compared to traditional frosted methods, offering both speed and protection for the print and paper surface.

**04 Advantages of Frosted Embossing**

– Creates a distinct three-dimensional feel with patterns and textures of varying depths, enhancing the artistic appeal of the printed product.

– Suitable for high-end packaging such as cigarettes, liquor, food, medicine, cosmetics, and crafts like New Year paintings, calendars, and advertising posters.

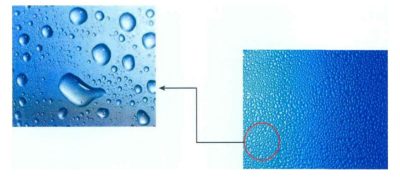

**05 Process Identification**

– **Reverse UV**: Surface is shiny with a greasy feel, easily scratched off with a blade; it is a printing UV process.

– **Frosted UV**: Surface has a frosted white effect and feel, easily scratched off with a blade; it is a screen printing UV process.

– **Frosted Embossing**: Surface has a dark matte effect and feel, cannot be scratched off with a blade; it is a frosted embossing process.