The Selection of Raw Materials for Self-Adhesive Label Printing

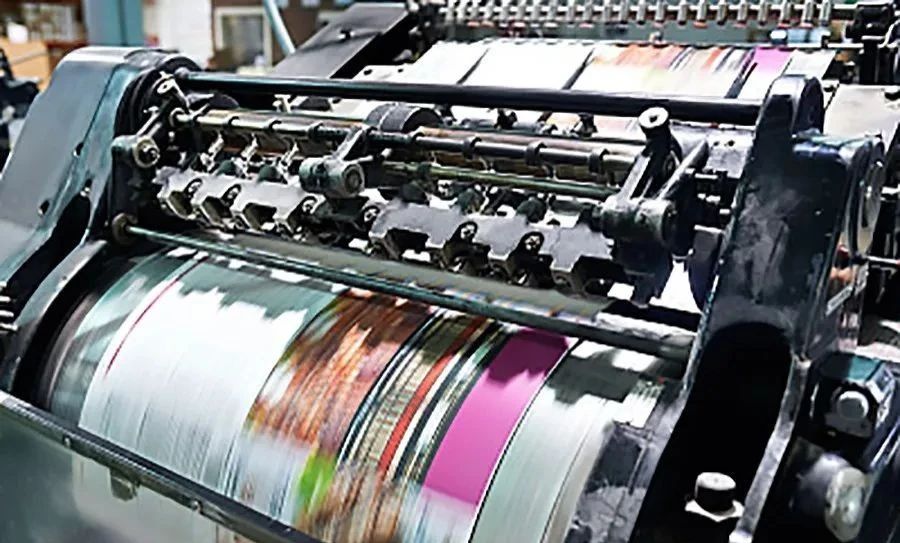

Self-adhesive label printing, a type of specialty printing, generally completes both printing and post-processing on a label machine in one go, meaning multiple processing steps are carried out at several stations on the same machine.

Process Flow of Self-Adhesive Label Printing

The quality control of self-adhesive label printing is a comprehensive issue involving printing and processing. It requires a holistic approach considering material selection, equipment configuration and adjustment, and the establishment of process routes. Additionally, tracking the application of label products at the customer’s site is crucial to further improve the quality of label products.

Selection of Raw Materials for Self-Adhesive Label Printing

When selecting raw materials, it is essential to choose high-quality self-adhesive materials that meet all physical and chemical indicators, rather than expired or unstable products. Although the latter may be cheaper, their unstable quality leads to high consumption in each process, potentially preventing equipment from processing normally. This not only wastes raw materials but also a significant amount of labor and resources, resulting in higher processing costs for finished labels. More seriously, it could lead to customer returns or even loss of customers.

Considerations for Raw Material Selection

1. **Characteristics of Self-Adhesive Label Printing and Processing**

– Consistency of surface gloss and color, uniformity of density on the facestock.

– These indicators determine the uniformity of ink absorption by the self-adhesive material and also affect the color difference of labels from the same batch. The coating strength of the facestock determines whether a large amount of paper dust will be generated during printing, which is also an important indicator of print quality.

2. **Uniformity and Strength Indicators of Self-Adhesive Label Backing Paper and Facestock Thickness**

– These indicators are not only related to printing performance but also crucial for determining the uniformity of die-cutting and the speed and paper edge breakage during waste removal. If these indicators are too low, the label machine cannot produce at high speeds.

3. **Flatness or Uniformity of Reel Tension of Self-Adhesive Label Materials**

– Whether it is sheet printing or reel printing, the flatness of the material determines whether it can be correctly fed, run, registered, and collected during printing.

– For reel materials, the reel tension significantly affects the flatness of the reel’s end face, whether glue penetration occurs, and whether correct registration is possible.

4. **Uniformity and Correct Amount of Adhesive and Silicone Oil Coating on Self-Adhesive Label Materials**

– These indicators directly affect the peel force (release force) between the label and the backing paper. The size of the peel force directly affects die-cutting waste removal and the machine’s speed. The peel force also determines the label’s dispensing condition, i.e., its application.

– Additionally, the amount of glue applied affects the glue penetration on the material’s end face. Therefore, it is crucial to carefully inspect and select materials with appropriate amounts of glue and silicone oil when purchasing self-adhesive materials.

By carefully considering these factors, you can ensure the quality and efficiency of self-adhesive label printing.