With the improvement of the consumer level, today’s businessmen are also more and more focus on the external packaging of products, pay more attention to safety and environmental protection, design. But have seen so many packages, do you know what are the most commonly used materials for packaging?

First, paper packaging materials

In the whole packaging design development process, paper packaging materials as a common packaging materials, is widely used in production, life practice. Paper is inexpensive, suitable for large-volume mechanized production, and good molding and folding, suitable for fine printing, and has the advantages of recyclable, economic and environmental protection.

1, kraft paper

Kraft paper has a high tensile strength, tear strength, rupture power and dynamic strength is very high. Tough and inexpensive, with good folding resistance, water resistance. Mostly roll paper, but also flat paper. Can be divided into single light, double light, stripes, grain-free, etc., the color is white and yellow-brown, mainly used for wrapping paper, envelopes, shopping bags, paper bags, cement bags, but also used for food packaging paper.

2, coated paper

Copperplate paper is also known as printing coated paper. Mainly wood, cotton fiber and other high-grade raw materials refined. Surface coating and varnish treatment to increase the smoothness and luster, divided into two kinds of single-sided and double-sided, the paper surface is divided into two kinds of glossy and cloth. The surface of the paper is smooth, high whiteness, good ink-absorbing and inking properties, reflecting all the colors in the spectrum and obtaining the best results, and little stretch. Not only that, but also divided into single copper (one side coated with varnish), double copper, matte copper and other types (matte coated paper for matte powder paper, more expensive than coated paper). Commonly used grammage 80g, 105g, 115g, 128g, 157g, 180g, 200g, 250g and so on. Suitable for color printing, mainly used for offset printing, gravure printing fine mesh prints, such as senior albums, calendars, books and magazines in the illustrations. Bright colors after printing, rich changes in levels.

3, whiteboard paper

Whiteboard paper is a white and smooth front, the back is mostly gray background of the cardboard, this cardboard is mainly used for one-sided color printing made of paper boxes for packaging use. The texture is hard and thick, with good strength, surface strength, folding resistance and printing adaptability, suitable for making boxes, lining boards, handmade products and so on.

4, corrugated cardboard

Corrugated cardboard with lightweight and strong, load and pressure resistance, shockproof, moisture and other advantages, and lower cost. Single-faced corrugated board is generally used as a protective liner for commodity packaging or to make lightweight kag and pads to protect commodities from shocks or impacts during storage and transportation; three-layer or five-layer corrugated board is used to make sales packages for commodities; and seven-layer or eleven-layer corrugated board is mainly used for the production of boxes for electromechanical products, furniture, motorcycles, and large home appliances, etc. Corrugated board is divided into two categories according to the flute type. Corrugated cardboard can be divided into seven categories according to the flute type: Pit A, Pit B, Pit C, Pit D, Pit E, Pit F, and Pit G. Pit A, Pit B, and Pit C are generally used for outer packaging, while Pit D and Pit E are generally used for small and medium-sized packaging.

5. Gold and silver cardboard

In order to highlight the grade of the printed packaging products, more and more customers choose to use gold and silver card to print, according to years of printing experience, will be gold and silver card in the printing of some of the issues needing attention to be sorted out as follows:Gold and silver card is a kind of special paper, unlike the general paper, they are divided into two kinds: bright gold card and matte gold card, bright silver card and matte silver card. It is in the single copper paper or gray board paper based on a layer of gold and silver foil film media, this material is not easy to absorb ink when printing, so in the printing to use a fast-drying ink to print.

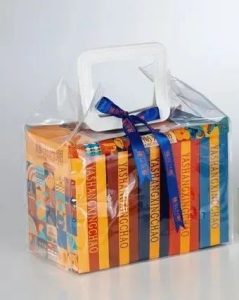

Second, plastic packaging materials

Various commodities used in packaging materials, usually mostly for one-time use, when the goods from the production unit circulated to the hands of consumers or to the commodities opened and used, packaging materials that completed its mission, as waste materials recycling or disposal.

Therefore, for packaging materials, one is the requirement of its performance to be good, to adapt to the protection, publicity needs of the commodity; two is the requirement of its cost to be as low as possible, in today’s so-called general-purpose plastics, such as polyethylene and polypropylene, which have excellent performance, large production volume, low prices and other common characteristics, is the first choice of material for plastic packaging materials.

Plastic has good water resistance, moisture resistance, oil resistance, insulation, and light weight, colorable, easy to produce, can be shaped into a variety of shapes and adapt to the printing, its raw materials from abundant sources, low cost, excellent performance, is one of the most important packaging materials in the modern sales packaging.

Common packaging plastic components are mainly polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyethylene terephthalate (PET).

Third, metal packaging materials

Metal is widely used in industrial product packaging, transportation packaging and sales packaging. Has excellent mechanical properties and barrier properties, good overall protection performance, beautiful appearance, good processing performance, abundant resources, waste disposal. Beautiful appearance, special metallic luster, easy to print and decorate. It is widely used in food packaging, pharmaceutical packaging, daily necessities packaging, instrumentation packaging, industrial packaging, arms packaging and other aspects. Which is used for food packaging in the largest number.

1, steel packaging

Compared with other metal packaging materials, steel is a richer source, cheaper, lower energy consumption and cost, with good plasticity and ductility. Its amount of metal packaging materials in the first place.

2, aluminum packaging

Aluminum is lightweight, excellent processing performance, has good ductility and corrosion resistance, not easy to rust, brightness beautiful and durable, easy to print, processing and recycling. Aluminum is mainly used for sales packaging, the most common such as cans. There are mainly pure aluminum sheet, alloy aluminum sheet, aluminum foil and aluminized film. Has a good corrosion resistance, some occasions also better than stainless steel, such as aquatic products with aluminum packaging will not be due to the decomposition of sulfides in the protein and the adverse phenomenon of metal sulfide blackening.

Fourth, glass, ceramic packaging materials

Glass has a high degree of transparency, impermeability and corrosion resistance, non-toxic, tasteless, chemically stable, low production costs, etc., can be made into a variety of shapes and colors of transparent and translucent containers. Ceramics have good chemical stability and thermal stability, can withstand the erosion of various chemicals, high temperature, rapid changes in heat and cold will not have an impact on the ceramics, is the ideal food, chemical packaging containers. Glass and ceramics belong to the silicate materials, glass and ceramic packaging refers to ordinary or special glass and ceramics made of packaging containers, such as glass bottles, glass jars, ceramic bottles and tanks, altars, pots and other containers.